TUE's SPUBOUND SYSTEMS

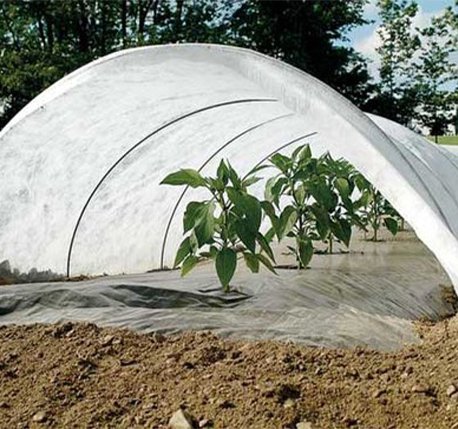

Single beam spunbound line.

Double beam spunbound line.

SSS triple beam spunbound line.

Top quality products with higher capacity yields.

Energy Efficient- Brilliant Dewatering and Drying Technology.

Carding machine crafted with carbon rollers and designed for high speeds.

Ensuring the efficiency for water recirculation and filtration.

Technical Consultation, Training, supervision to the clients with the flexibility for trials to ease customers.