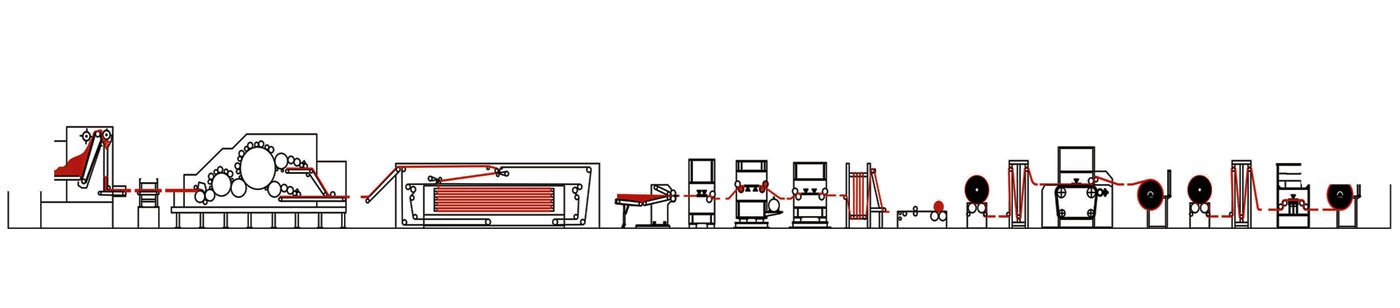

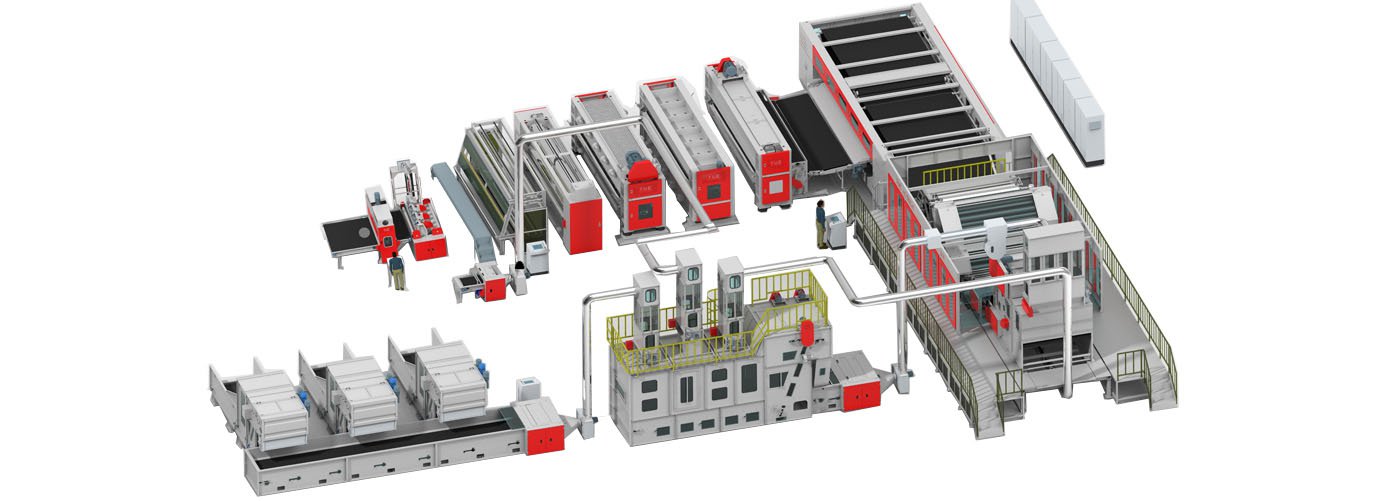

TUE's GLASS FELT SYSTEMS

A wide variety of the Nonwoven glass fiber felts for different applications.

Automotive Insulations and filteration felts.

Excellant property of strength, elongation, shrink resistant.

Antistatic flame retardant functions.

Ease of moldng into various car or coat components.

Blended with different synthetic fibers such as polyester, or prolypropylene fibers.

Carding wires are configured in accordance with the features of glass fibers.