Geomembrane Application

Site drainage management

Slope reinforcement, Erosion control

Road construction

Railroad repair

Landfill lining and stabilization

Earth retaining structures

French drains

Underlayment fabric

Nonwoven geotextile fabric is widely used medium weight nonwoven geotextile line that is perfect for drainage, asphalt overlay and various other filtration projects.

These needle-punched geotextiles are known for their ability to help with separation, reinforcement, drainage, filtration, erosion protection, and slope stabilization.

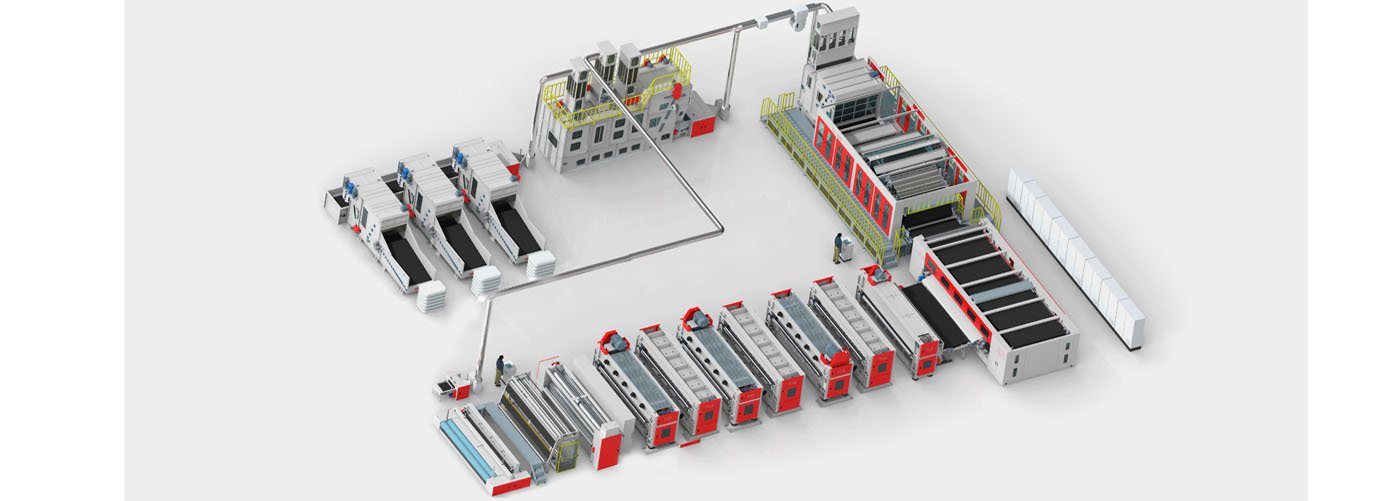

TUE HI-TECH offers a complete assistance from the project inception to the final production.

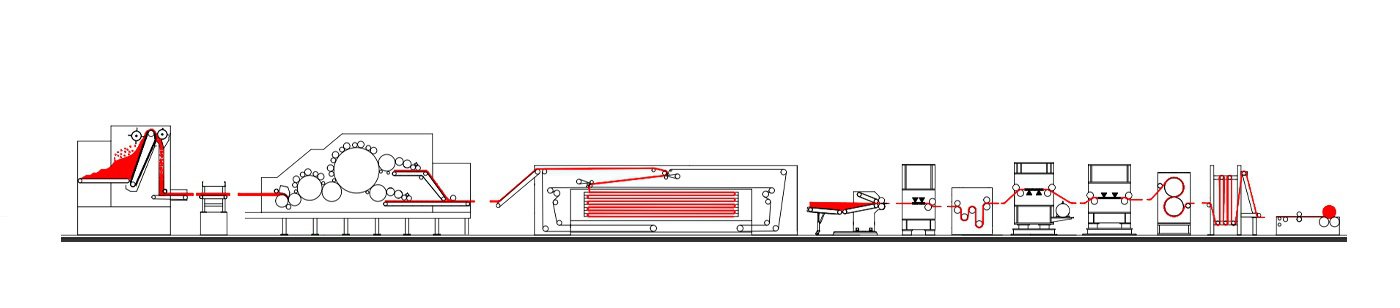

Geononwovens are often made from polyester staple fiber and polypropylene fibers using the carding/compositing process. The card feeder (Multi-feed) forms a very even, compact web

from the fiber tufts. An auto-leveling device or weighing control is kept before carding in order to control the feeding speed of the card and detect the grammage variation. In the carding the fibers are carded and mixed and therefore, the better web batt is formed.

Site drainage management

Slope reinforcement, Erosion control

Road construction

Railroad repair

Landfill lining and stabilization

Earth retaining structures

French drains

Underlayment fabric

Nonwoven geotextile fabrics are produced by series of needle punchings at various rpms and needling densities in order to produce geofelts of higher tensile strength and the dimensionally stable nonwoven fabrics. Depending upon the speed and the densities of the final fabric, the needle punching lines are derived with several machine configurations. An addition of web drafter after crosslapping is intended to form the fabric with lesser densities and increase the speed. However, some producers prefer to add on the Zeta drafter after the pre-needling loom.

| Raw Material | Polyester staple fibers, PP Fibers |

| Product Width | 2500mm- 9000mm |

| Product Density | 120-1000gsm |

| Craftwork | Needle punching and calender |

GEOTEXTILE PRODUCTION LINE: SUITABLE FOR ALL KINDS OF GEOSYNTHETICS AND GEOBAGS.

CONTACT USWith the spunlace systems, (including carding system, Jetlace hydroentanglement system, dewatering unit, through-air dryer, and twin embossing calender), TUE offers a complete solution with higher productivity and very attractive energy efficiency for production of spunlace fabrics. The process for spunlace exists in direct or crosslapping configurations.

YOUR NONWOVEN MACHINES ARE JUST A CLICK AWAY-

CONTACT US