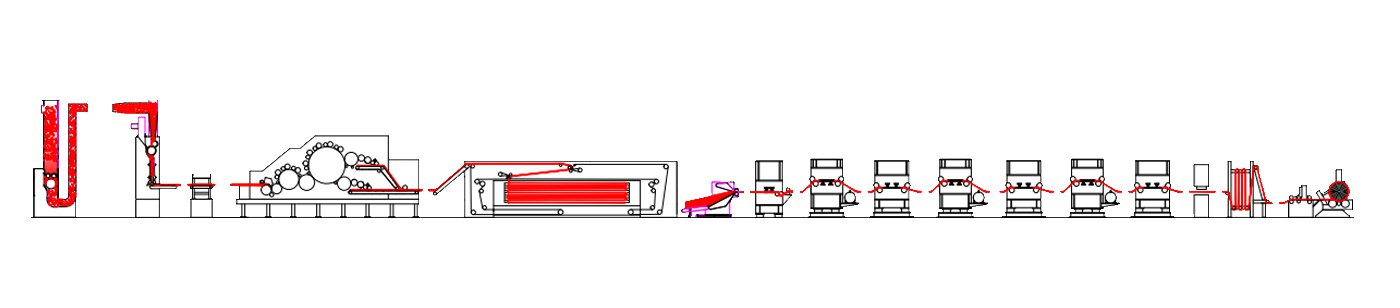

TUE's Configuration for Cleaning wipes

For all kinds of kitchen and industrial cleaning.

Fibres can be any polyster fibers mixed with viscose fibers.

Configurations of the number of needle punchings are designed as per the need.

Technical Consultation, Training, supervision to the clients with the flexibility for trials to ease customers.