TUE's ARTIFICIAL LEATHER LINE

Abrasion resistance series for shoes.

Artificial leather substrate felts are manufactured through the series of the needle punching looms.

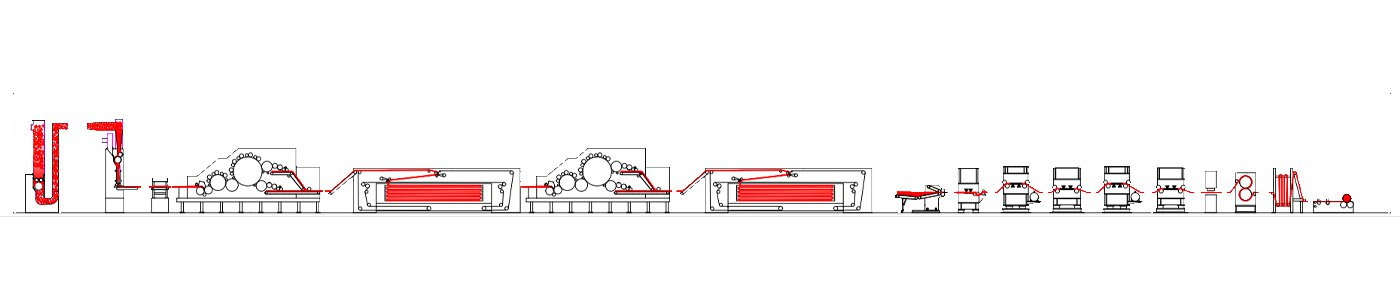

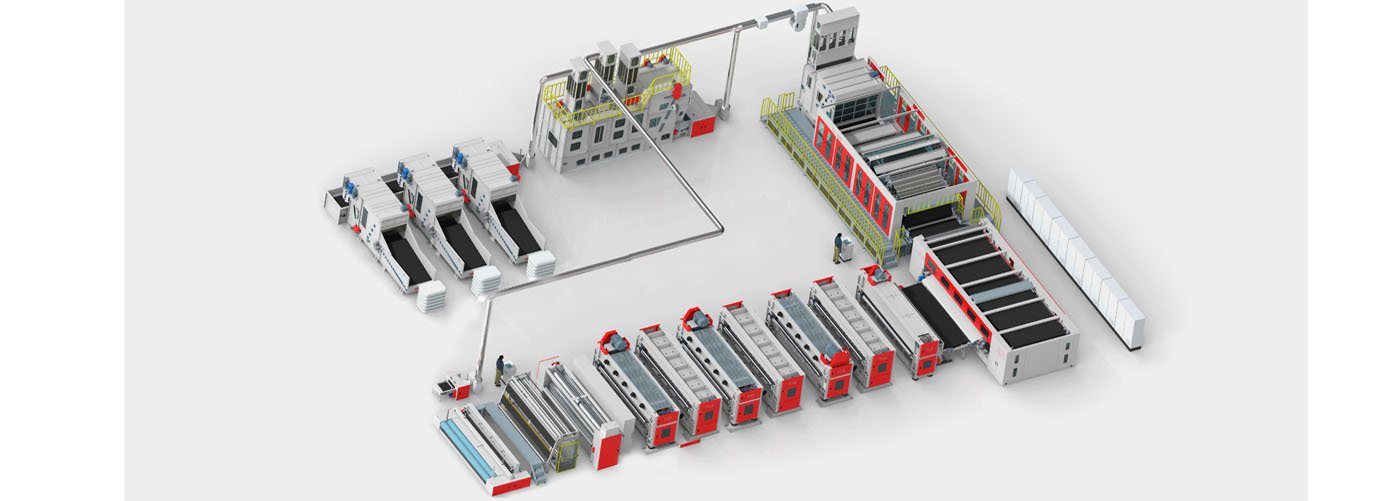

Mostly in order to focus on achieving uniformity of the web, a very fine synthetic fibers basically with fine denier 1-3 dtx, mixed with the bicomponent fibers are fed into the opening stage. The finely opened and blended fibers in the multimix chambers are transferred to the feeder which forms the batt and feeds to the carding. The roller card running at very high speed opens up the fiber flocks thoroughly. A cross lapper lays the layers of the web of layers controlling the CV of the webs at the edges as the lapper are equipped with high end servo motors to control the movement of lattice and deposition of the web. The web is then continuously needle punched up to 1-11 high speed needle punching machines in order to ensure the good surface quality.

Depending upon the requirement of the needle punches per square meter in the fabric, the needle looms either single board or double board or sometimes four boards are configured in the line. This process allows denser stitch densities which is important for good bonding of the fibers in the material.

Nonwoven artificial leather uses special punching methods to increase the density of the fiber sheets, After setting, a solid and strong material called nonwoven needle punched felt is formed. The process also involves online or offline calendering. Depending on the application the felts are further coated either with PU/PVC or bitumen.

The application of this felt is on various uses such as shoes lining and counter lining, leather goods lining, belt -bag liner, PVC/ PU backing substrate, microfiber material.

Abrasion resistance series for shoes.

Nonwoven artificial leather uses special punching methods to increase the density of fiber sheets. After setting, a solid and strong material, called the nonwoven needle punched felt is formed. Appearance and applications are like artificial leather. Application: Shoes Lining and Counter Lining, Leather Goods substrate, Microfiber Material.

| Raw Material | Polyester staple fibers, Micro fibers, bicomponent fibers |

| Product Width | 1500mm, 3600mm |

| Product Density | 120-1000gsm |

| Craftwork | Needle punching and calender |

SPUNLACE SOLUTION: WITH DIRECT AND CROSS LAPPING SOLUTIONS FOR ULTRALIGHT PRODUCTS.

CONTACT USWith the needle punching systems, (including carding system, cross lapper, high density needle punching looms, hot calender), TUE offers a complete solution with higher productivity and very attractive energy efficiency for production of artificial leather substrate. The process further includes PU/ PVC or bitumen coating.

YOUR NONWOVEN MACHINES ARE JUST A CLICK AWAY-

CONTACT US