TUE's AIRLAYING SYSTEMS

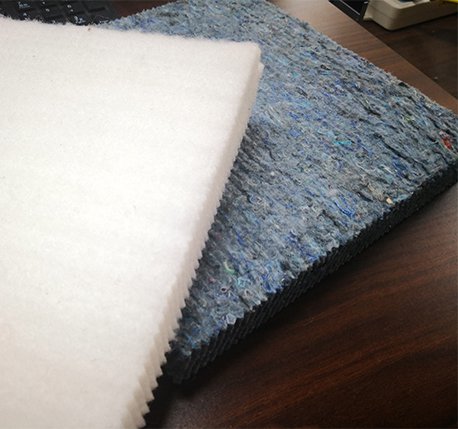

Airlaying through special guide mechanism to ensure even air flow and the air pressure.

Machine adjustment for the process of different fiber types and web weights.

Sets the final thickness and gives the direction and orientation to the fibers.

Ensures evenness both longitudinally and across the whole width of the machine.

Applicated areas: Automotive, Agriculture, Home furnishings, Buildings panels, Sound proofings,

Thermal Insulations, Clothings and interlinings.