The nonwoven fabric have wide range of the applications for households. This process helps to produce the kitchen cleaning pads also called scouring pads. Considering the volume production, this has wider application for industrial use called abrasive pads or industrial pads.

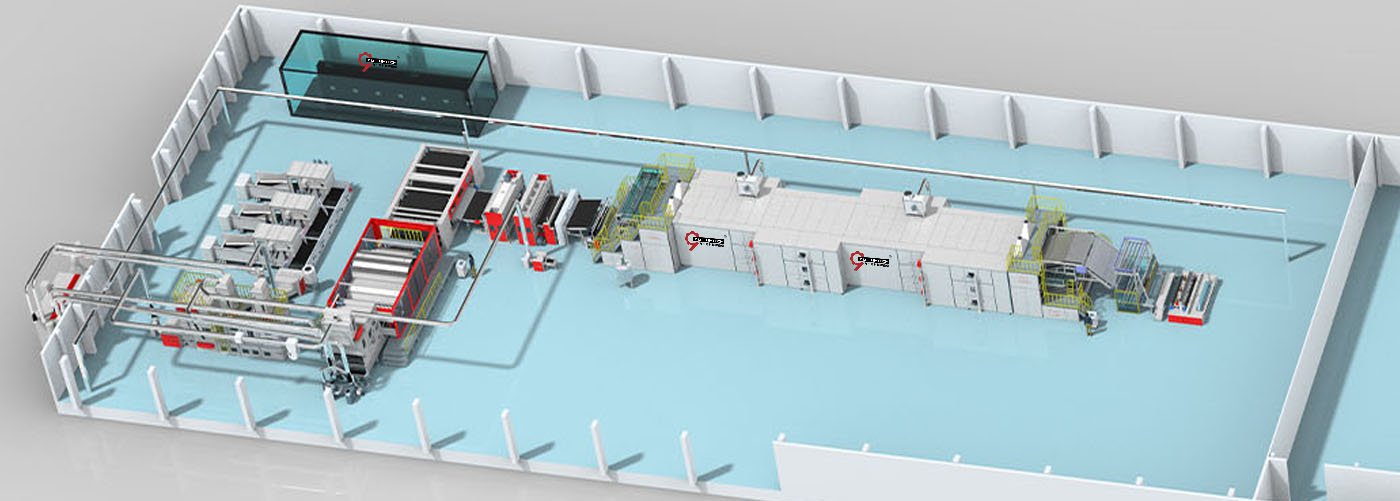

TUE HI-TECH offers a complete solution for producing both kitchen cleaning pads and the industrial use abrasives.

This process is most widely producing the kitchen scrubbers. Also called the 3 layer spray and dipping unit for abrasive use.

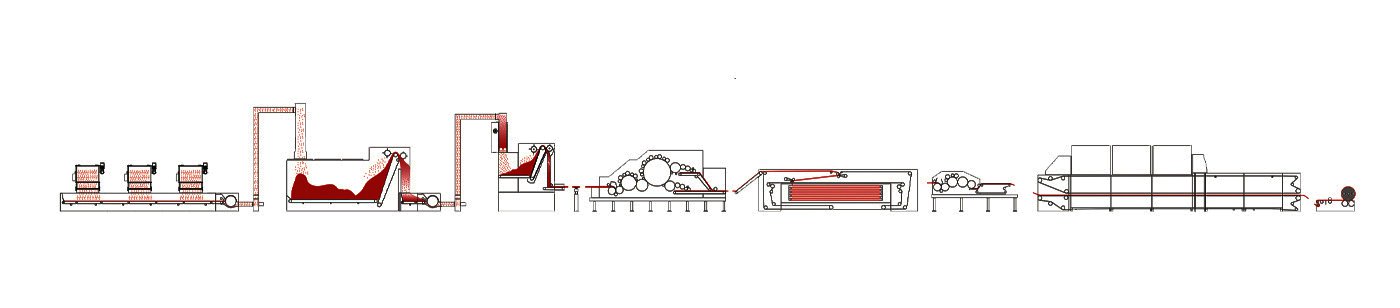

Unlike other nonwoven fabrics, this process uses dense fibers with higher fiber deniers such as 30Denier up to 100 Denier polyester fibers. Sometimes these polyester fibers are mixed with Polyamide fibers or nylon fibers. ( PA6, PA66, NYLON 6, NYLON 66 fibers). After undergoing normal web formation process through carding and cross lapper, these fabrics are passed on to dipping unit to coat the abrasive resins and then heated in a very long and triple layer -3 layer spray oven. The spray oven also have the separate spray stations to spray the acrylic and then undergo thermal bonding of the resins and the nonwoven web.

The pigments for coloring are added in the oven spray stations or dipping units. For the industrial abrasives, upon requirements, a finishing machines can be provided to shape up the abrasive hand pads into abrasive wheels.