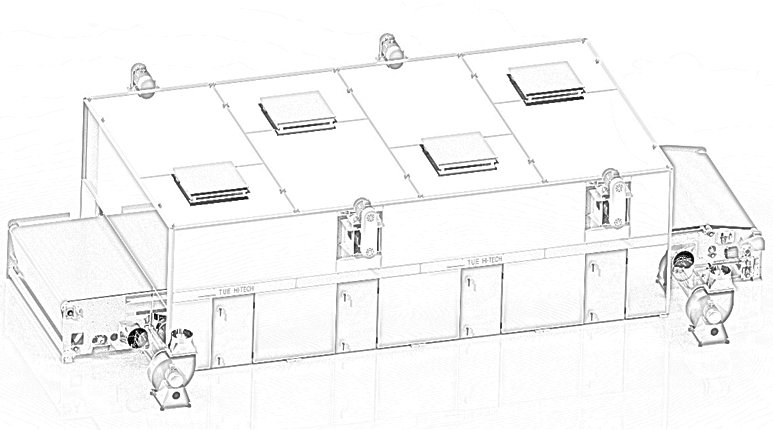

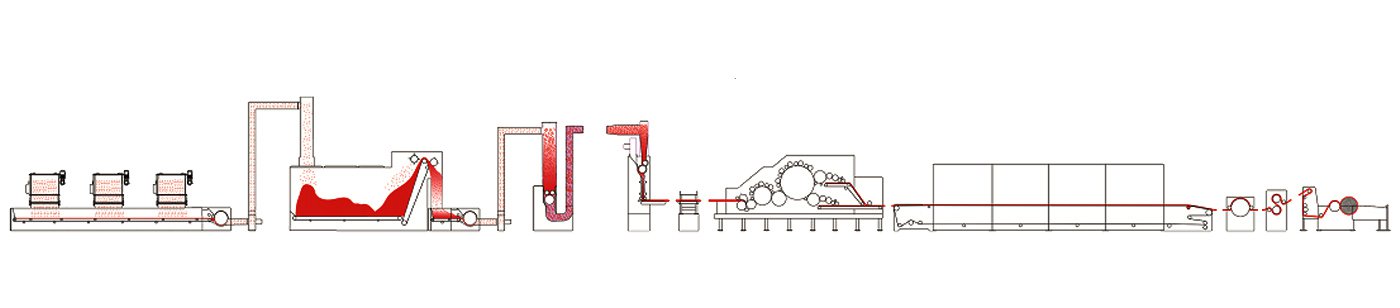

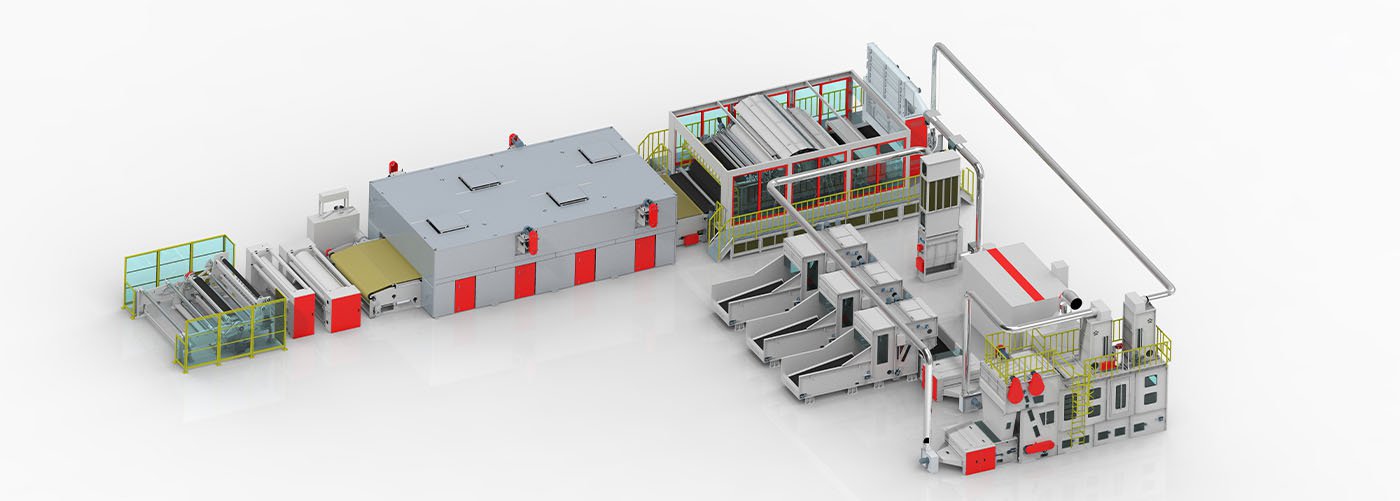

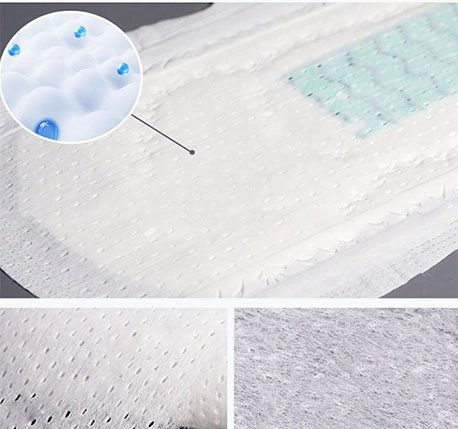

Hot air through bonding line is a type of thermal bonding that involves the application of heated air to the surface of the nonwoven fabric. During this air through bonding process, heated air flows through holes in a plenum above the nonwoven material. Unlike other thermal ovens, which push air through the material, the through air oven process uses negative pressure of suction to pull the air through an open conveyor belt (either with stainless steel belt or the holding nonwoven as it is drawn through the oven. Pulling air through the material allows the rapid and even transmission of heat to minimize distortion of the nonwoven material.

This process is most widely famous for hygiene products, filtration materials, bedding, furniture, carpet backing, cleaning wipes, dryer sheets, and other durable end use disposable products. In addition to the desirable characteristics provided by this process, a versatile nonwoven material is well developed, which is benefitted being lightweight and safer for the environment.

It belongs to a type of hot air bonding (hot rolling, hot air) non-woven. Hot air non-woven fabric is formed by the short fibers after carding, and the hot air on the drying equipment is used to penetrate the web to be heated and be bonded.