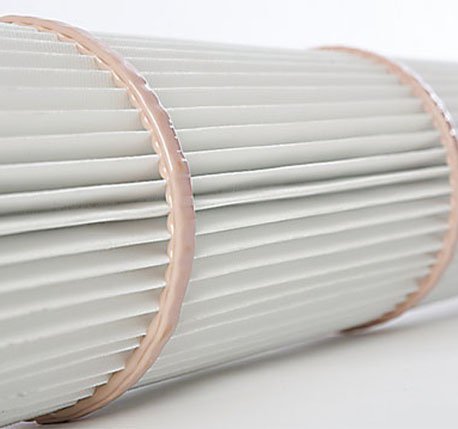

The spunlace non-woven fabric is no exception, but it is composed of multiple layers of fibers, and it contains a wide range of fibers, and its fiber raw materials are diverse.

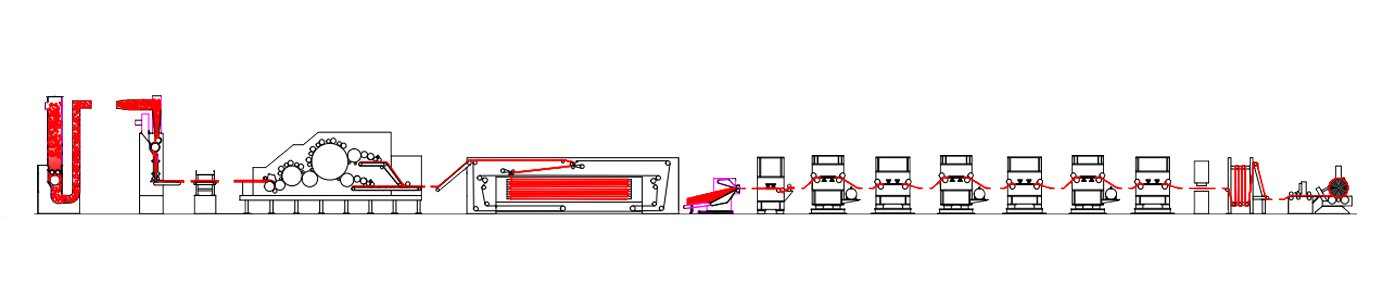

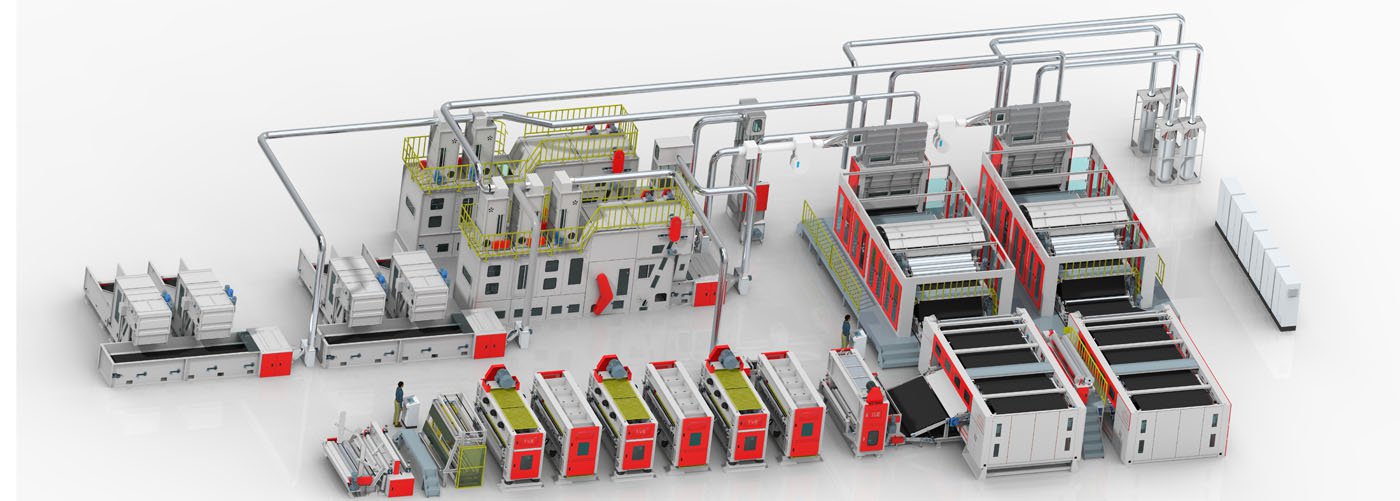

TUE HI-TECH offers a complete TURNKEY Spunlace Systems.

This process is most widely famous for hygiene, medical and the skincare fabrics. Also called the HYDROENTANGLEMENT or water jet process.

The water jet displaces part of the surface fibers in the fiber web, including vertical movement to the opposite side of the fiber web. When the water jet penetrates the fiber web, it is rebounded by the net curtain or the rotating drum and scattered to the fiber web in different directions. The opposite. Under the dual effects of the direct impact of the water jet and the rebound water flow, the fibers in the fiber web are displaced, interleaved, entangled, and entangled, forming countless flexible entanglement points, thereby strengthening the fiber web.

The purpose of dehydration is to remove the retained water in the fiber web in time, so as not to affect the tangling effect during the spunlace. After the spunlace process is completed, the moisture in the fiber web is reduced to a minimum, which is beneficial to reduce drying energy consumption.