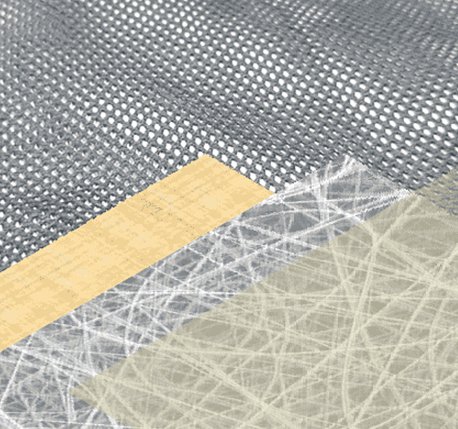

Fiber nanoization is the key to the preparation of higher efficiency and value-added nonwovens. Quality electrospun nanofibers have so far been difficult to industrialize.

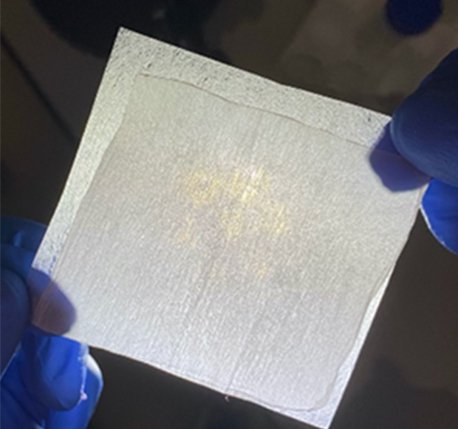

TUE HI-TECH offers technology to manufacture the core products like nanocomposites degradable medical materials, nanocomposite natural-antibacterial hygiene material, water soluble nanocomposites new medical and aesthetic materials.

The products developed with this technology cannot only increase the competitiveness of single region, it can leas the transformation and upgrade global nonwoven manufacturing industry to provide high end products.

The nonwoven fabrics are adapted to meet the needs of the international and local needs of medical and health markets.

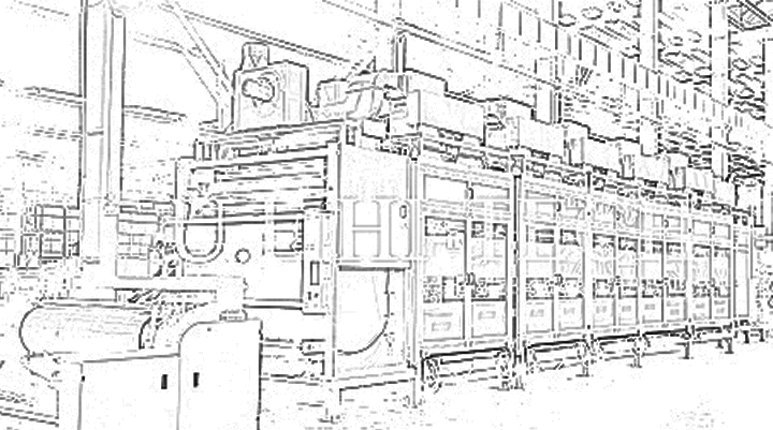

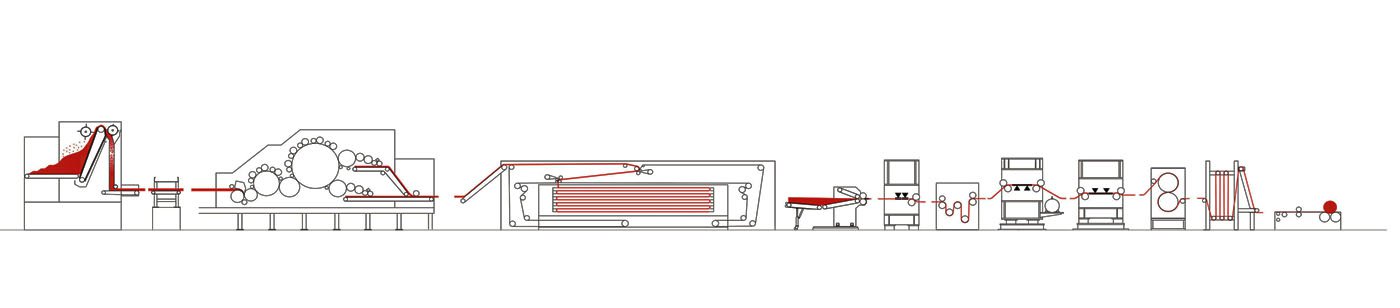

The entire electrospining process includes:

(1) Upper base fabric unwinding work area; (2) Electrospinning main box area; (3) A total of 10 sets of "spinning modules"; (4) Lower Base cloth unwinding work area; (5) Solvent wind coax box; (6) Finished product winding work area; (7) Temperature and humidity control system; (8) Conveying net curtain. (9) Fans and pipe connections necessary for dehumidification air intake, main box exhaust, and solvent air coax box exhaust.