TUE's Carbon Nonwoven

Electrically conductive

Better thermal conduction

Ensure tensile strength

Higher quality composite componets

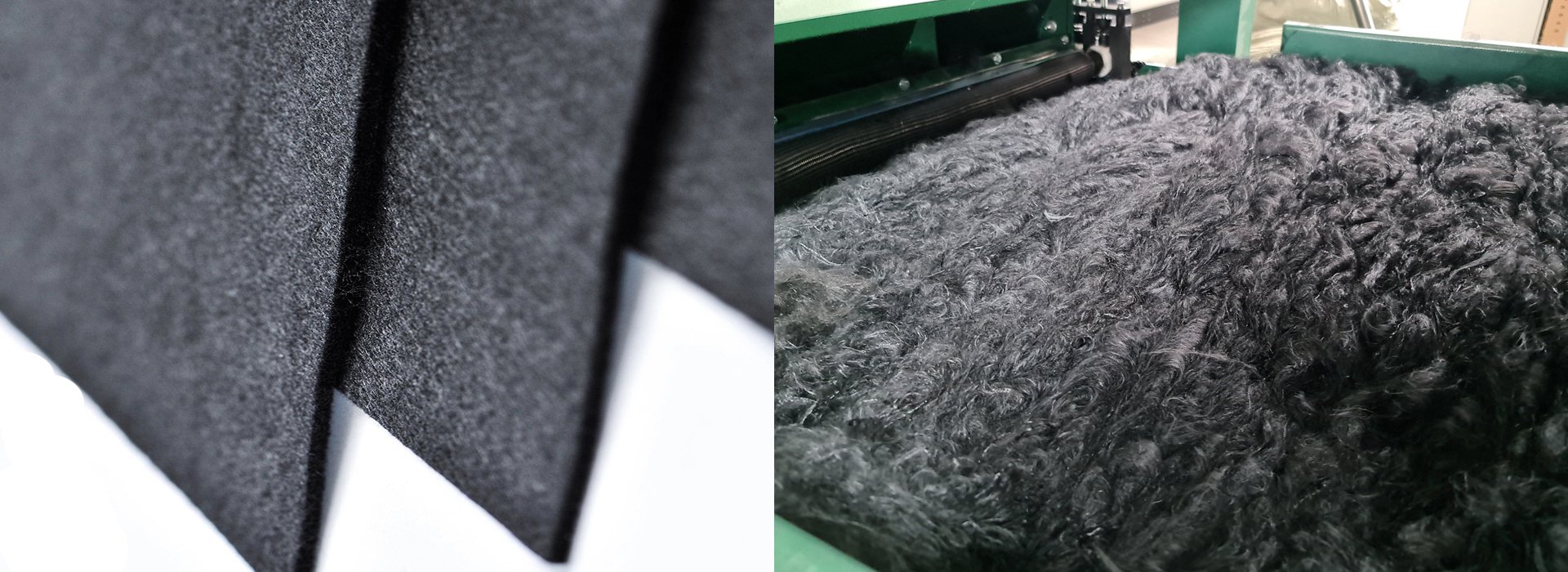

lightweight carbon fiber felt

Nonwoven carbon fiber composites are generally made of the carbon fibers through the series of needling process.

Carbon fibers are known as re-inforcing agents, hence these carbon fiber composites are rich in manufacturing felts that has re-inforcement between the layers.

TUE HI-TECH offers a developing carbon fiber composite felts.

These felts are electrically conducive that ensures the thermal conduction. Carbon composites are better options replacing the normal synthetic felts. These are used in automotives as fire proof and heat retardant needle punched felts.

Electrically conductive

Better thermal conduction

Ensure tensile strength

Higher quality composite componets

lightweight carbon fiber felt

Unlike other needle punched felts, carbon fiber composites uses carbon fibers instead of synthetic fibers. Carbon fiber fabirc is often needle punched making it more coarse and rigid than other synthetic fabrics. With possible range of applicated areas like aerospace, and automotive industries, carbon composites can be of several benefits.

| Raw Material | Carbon fibers |

| Product Width | 1500mm, 3600mm |

| Product Density | 120-500gsm |

| Craftwork | Needle punching |

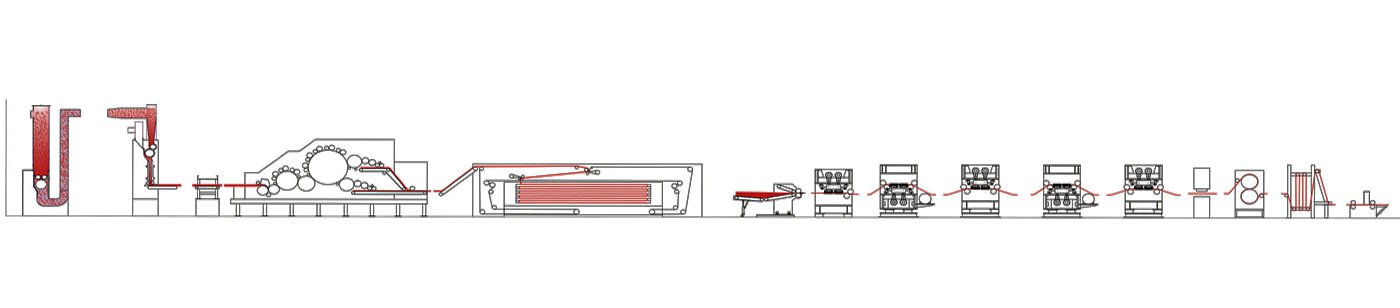

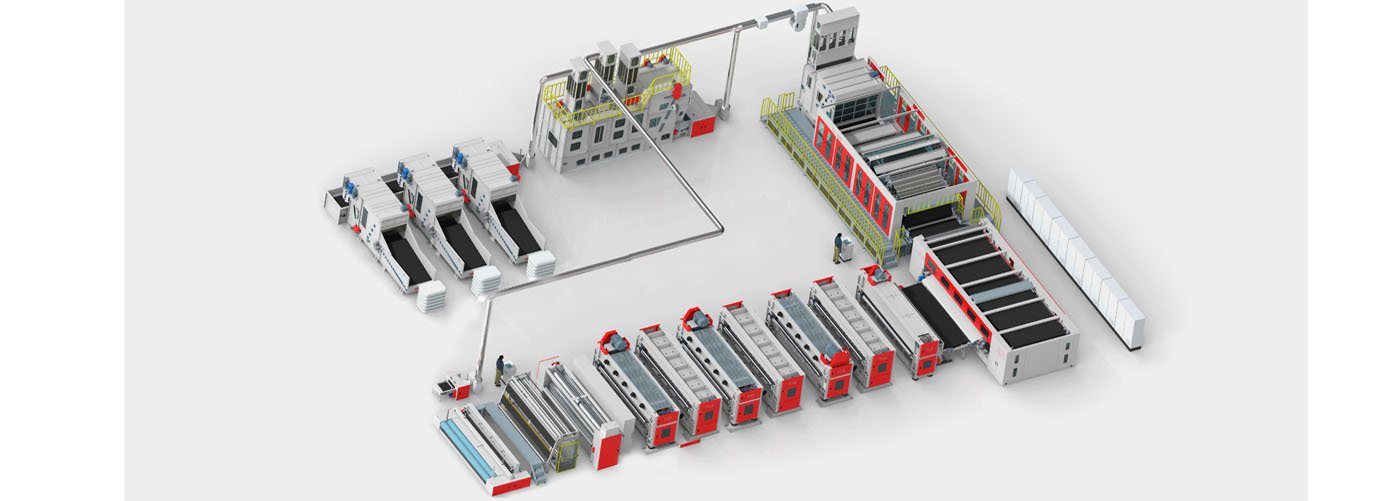

NEEDLE PUNCHING UNITS: DESIGNED FOR CARBON FIBER COMPOSITES

CONTACT USYOUR NONWOVEN MACHINES ARE JUST A CLICK AWAY-

CONTACT US