SINGLE MACHINE

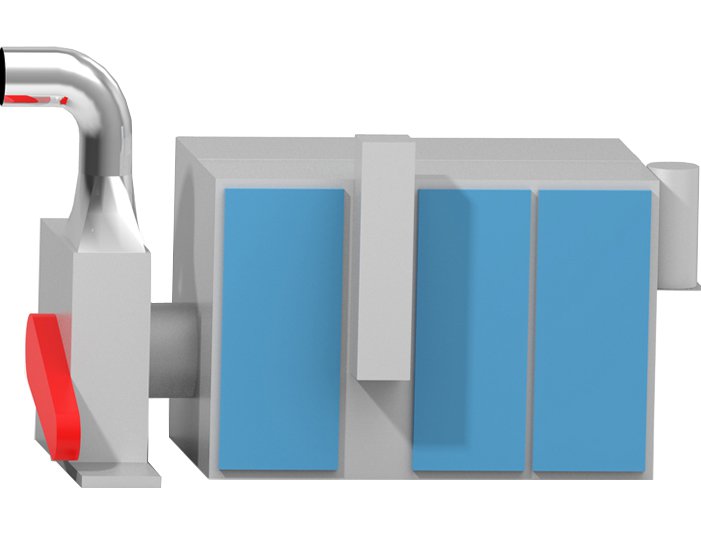

DUCTING FOR TRANSPORT

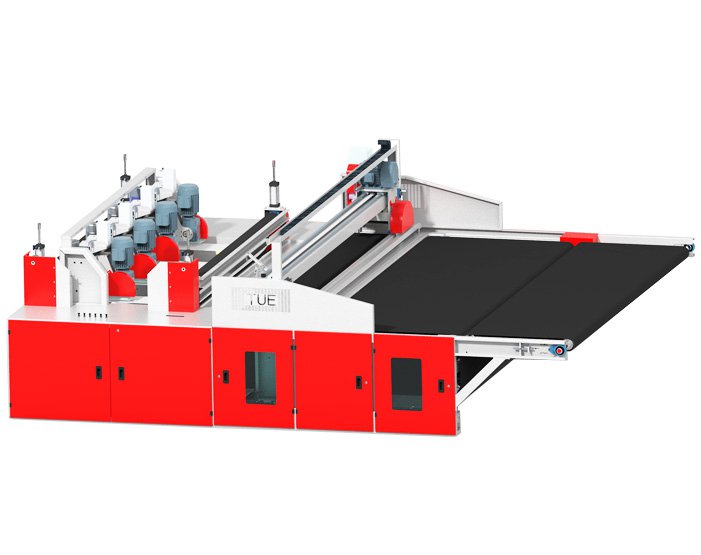

The entire nonwoven production process is basically all about the fibers. The fibers get fed to respective machines and converted to the desired fabric in terms of applications. The process is aided by the pipes or ducts so as to transfer the fibers to next process and ensure continuous flow.

These pipes or duct are supplied with respective bends.

As for the pre-opener, it also includes a long horizontal PVC conveyor, called transversal conveyor to collect the fibers dropped by bale opener and feed into pre-opener. The fibers in the opener after opening are directed to the mixing machine with the help of blower fan